At Adamar Anchor & Chain, we understand how challenging it can be for technical teams and vessel operators to find class-certified mooring equipment that meets both quality and delivery expectations. Our solution is simple but powerful: we unite class-approved foundries and our own ABS-certified workshop under one coordinated system — ensuring reliability from casting to final assembly.

The Challenges in Mooring Equipment Supply

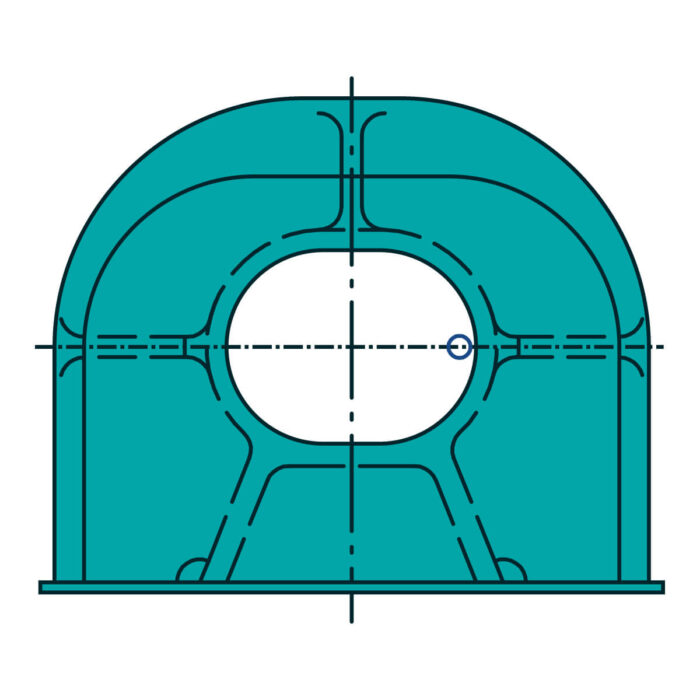

Steel Casting:

Steel-cast mooring products such as chocks, fairleads, and rollers are often difficult to procure quickly. The casting process requires molds, qualified foundries, and class supervision — all of which make production lengthy. Even under ideal conditions, manufacturing lead time can easily reach 3–4 months.

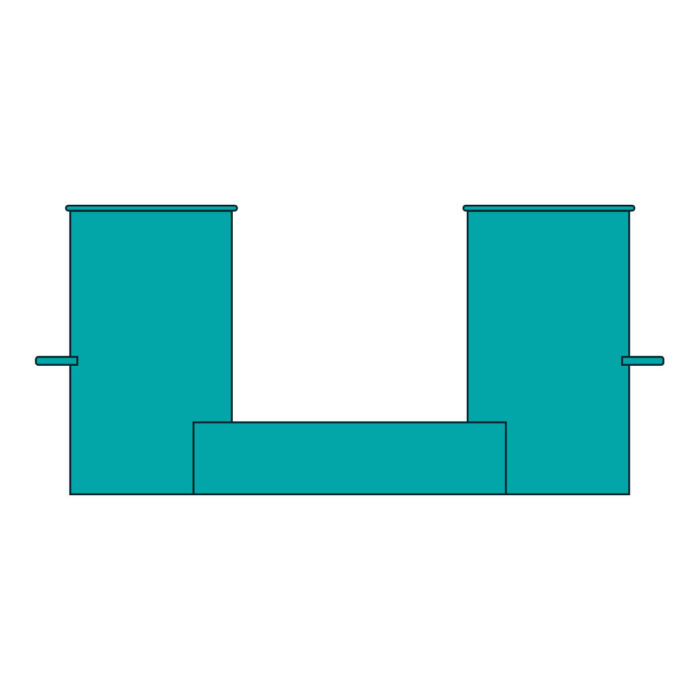

Welding and Fabrication:

Once the steel-cast parts are ready, they must be machined, welded, and assembled with other structural components like seats, shafts, and pedestals. This requires a skilled workshop with certified welders and high-precision equipment.

What Makes Adamar Different?

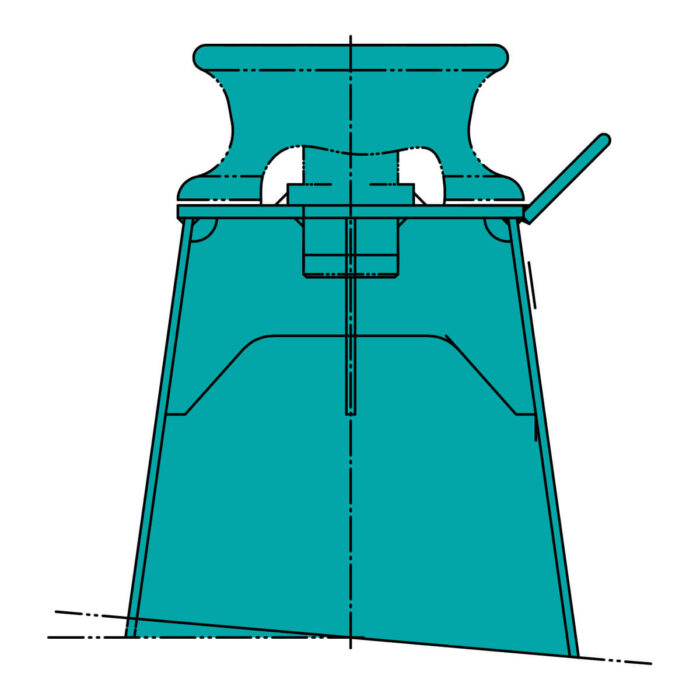

We differentiate ourselves by stocking common cast mooring components and integrating fabrication in-house. We maintain ready stock of frequently used steel-cast products, such as chocks and rollers, allowing immediate delivery to our clients.

Our Adamar Workshop, certified by ABS, handles machining, cutting, assembly, and welding — ensuring flawless fitment and high-quality finishing.

By combining these two disciplines — casting and fabrication — Adamar Anchor & Chain provides a unique one-stop solution for mooring equipment needs, saving our clients both time and cost.