Bollards

Bollards are essential mooring fittings designed to secure mooring lines safely on the deck. They transfer the line load from ropes or wires to the ship’s structure, ensuring safe and stable mooring in all weather and tidal conditions.

At Adamar Anchor & Chain, we supply class-certified steel-welded bollards designed and manufactured in full accordance with ISO 13795 and ISO 13797 standards. All bollards are fabricated and welded by ABS-certified welders in the Adamar Workshop, using high-strength marine-grade steel.

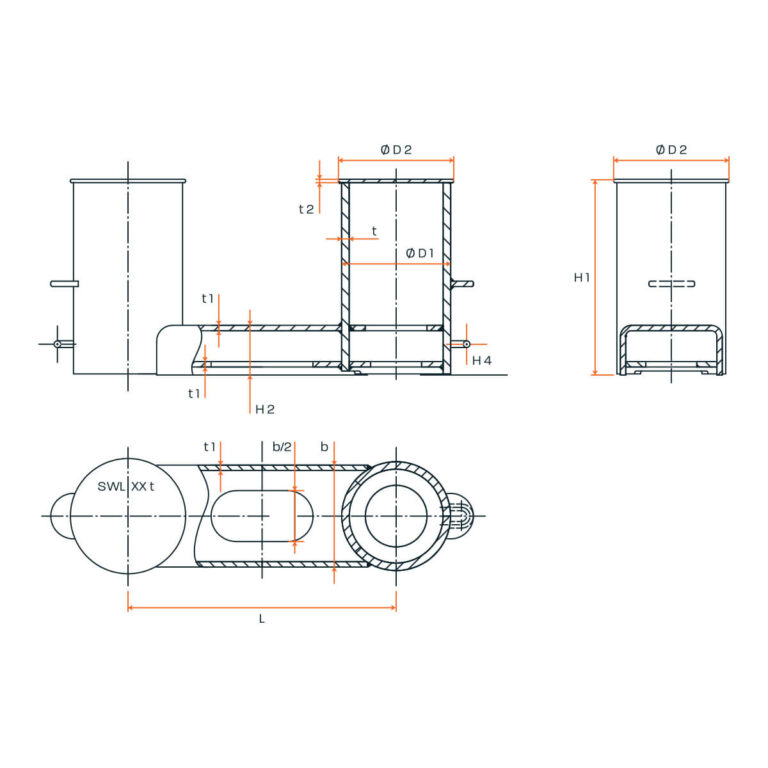

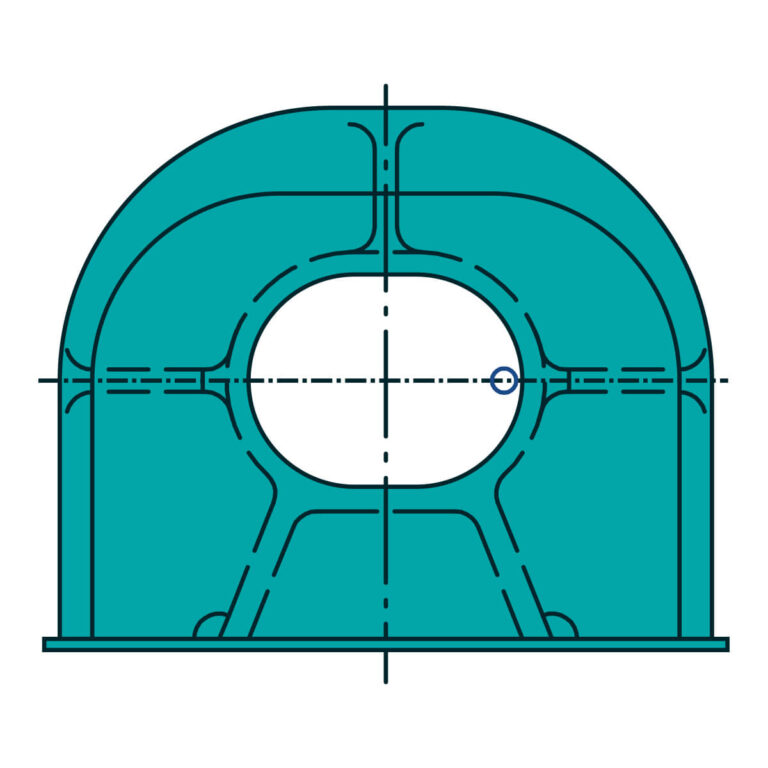

Type-A bollards are the most common design used for mooring operations on merchant and naval vessels. They are fabricated as double-bitt configurations and welded on deck foundations with a wide base plate for even load distribution.

| Steel Welded Bollards Type-A – DIMENSIONAL TABLE (mm) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom. Size | D1 | D2 | D3 | D4 | H1 | H2 | H3 | H4 | E | L | b | t | t1 | t2 | SWL | |||||

| For mooring purpose | For towing purpose | |||||||||||||||||||

| One-rope use | Two-rope use | |||||||||||||||||||

| kN | ton | kN | ton | kN | ton | |||||||||||||||

| 250A | 267,4 | 290 | - | 160 | 505 | 135 | 90 | 75 | - | 630 | 250 | 12 | 9 | 8 | 156 | 16 | 134 | 14 | 265 | 27 |

| 250B | 267,4 | 290 | - | 160 | 505 | 135 | 90 | 75 | - | 630 | 250 | 10 | 8 | 7 | 127 | 13 | 108 | 11 | 216 | 22 |

| 300A | 318,5 | 340 | 150 | 185 | 600 | 150 | 110 | 85 | 300 | 800 | 290 | 21,5 | 16 | 9 | 332 | 34 | 306 | 31 | 608 | 62 |

| 300B | 318,5 | 340 | 150 | 185 | 600 | 150 | 110 | 85 | 300 | 800 | 290 | 12 | 9 | 9 | 186 | 19 | 161 | 16 | 353 | 36 |

| 350A | 355,6 | 380 | 170 | 200 | 685 | 175 | 130 | 105 | 350 | 890 | 340 | 26 | 19 | 11 | 443 | 45 | 418 | 43 | 834 | 85 |

| 350B | 355,6 | 380 | 170 | 220 | 685 | 175 | 130 | 105 | 350 | 890 | 340 | 14 | 10 | 9 | 244 | 25 | 216 | 22 | 491 | 50 |

| 400A | 406,4 | 430 | 190 | 230 | 730 | 185 | 145 | 115 | 380 | 1000 | 380 | 28 | 20 | 13 | 594 | 61 | 521 | 53 | 1 040 | 106 |

| 400B | 406,4 | 430 | 190 | 250 | 730 | 185 | 145 | 115 | 380 | 1000 | 380 | 15 | 11 | 11 | 326 | 33 | 269 | 27 | 657 | 67 |

| 450A | 457,2 | 480 | 210 | 265 | 770 | 195 | 160 | 120 | 410 | 1100 | 425 | 29 | 21 | 14 | 753 | 77 | 612 | 62 | 1 216 | 124 |

| 450B | 457,2 | 480 | 210 | 285 | 770 | 195 | 160 | 120 | 410 | 1100 | 425 | 14,5 | 11 | 11 | 382 | 39 | 292 | 30 | 765 | 78 |

| 500A | 508 | 530 | 235 | 295 | 830 | 230 | 200 | 150 | 460 | 1250 | 480 | 32 | 23 | 16 | 992 | 101 | 757 | 77 | 1 511 | 154 |

| 500B | 508 | 530 | 235 | 320 | 830 | 230 | 200 | 150 | 460 | 1250 | 480 | 14,5 | 11 | 11 | 457 | 47 | 326 | 33 | 912 | 93 |

| 550A | 558,8 | 580 | 255 | 330 | 900 | 270 | 200 | 180 | 540 | 1380 | 520 | 31 | 22 | 16 | 1 131 | 115 | 812 | 83 | 1 619 | 165 |

| 550B | 558,8 | 580 | 255 | 350 | 900 | 270 | 200 | 180 | 540 | 1380 | 520 | 21 | 16 | 11 | 781 | 80 | 541 | 55 | 1 560 | 159 |

| 600 | 609,4 | 630 | 280 | 365 | 950 | 300 | 200 | 200 | 600 | 1550 | 560 | 33 | 23 | 16 | 1 401 | 143 | 948 | 97 | 1 893 | 193 |

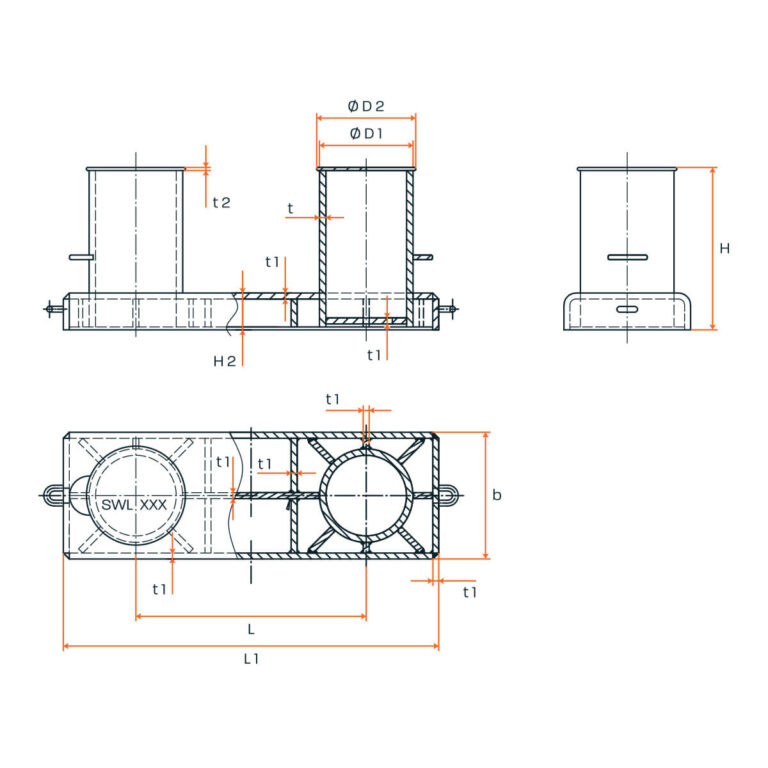

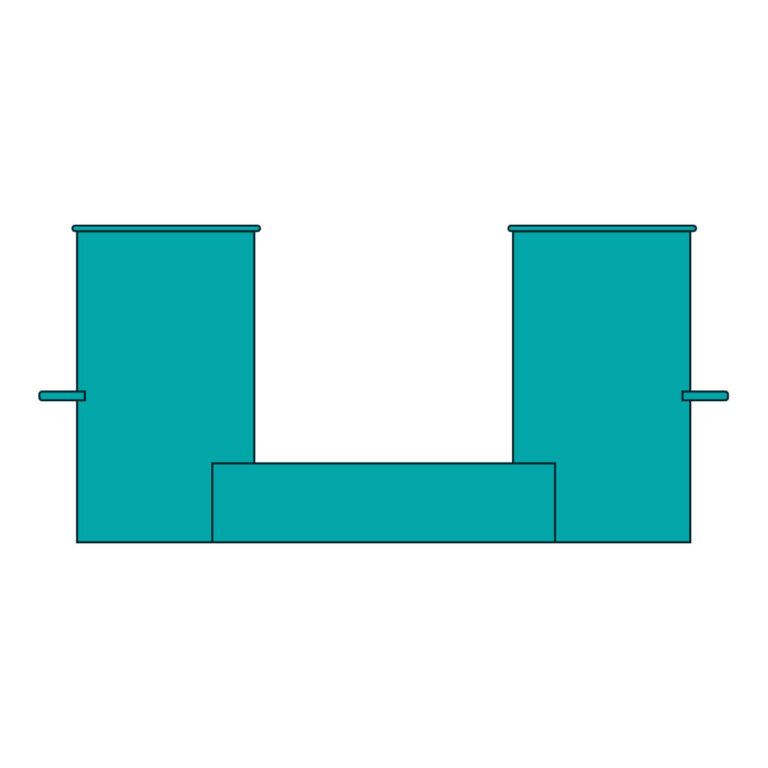

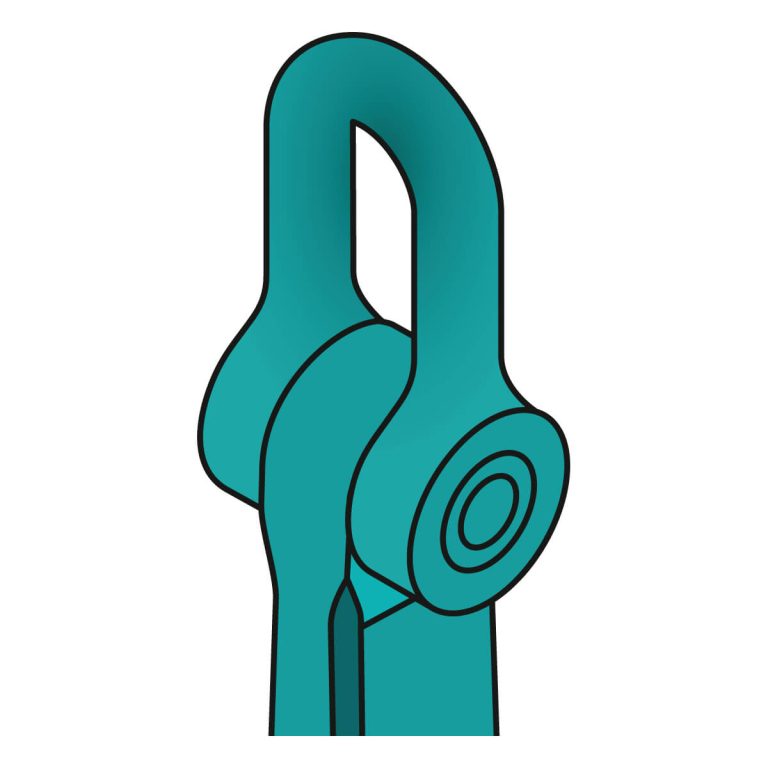

Type-B bollards feature angled or offset bitts, designed to optimize rope angles on the deck where space is limited or rope leads differ between bow and stern directions.

All Type-B bollards are welded constructions, machined to exact tolerances, and delivered with class certification upon request.

| Steel Welded Bollards Type-B – DIMENSIONAL TABLE (mm) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom. Size | D1 | D2 | H1 | H2 | L1 | b | t | t1 | SWL | |||||

| For mooring purpose | For towing purpose | |||||||||||||

| One-rope use | Two-rope use | |||||||||||||

| kN | ton | kN | ton | kN | ton | |||||||||

| 250A | 267,4 | 290 | 470 | 100 | 1065 | 360 | 12 | 11 | 156 | 16 | 134 | 14 | 265 | 27 |

| 250B | 267,4 | 290 | 470 | 100 | 1065 | 360 | 10 | 8 | 127 | 13 | 108 | 11 | 216 | 22 |

| 300A | 318,5 | 340 | 575 | 125 | 1300 | 430 | 21,5 | 20 | 332 | 34 | 306 | 31 | 608 | 62 |

| 300B | 318,5 | 340 | 575 | 125 | 1300 | 430 | 12 | 9 | 186 | 19 | 161 | 16 | 353 | 36 |

| 350A | 355,6 | 380 | 655 | 145 | 1475 | 480 | 26 | 23,5 | 443 | 45 | 418 | 43 | 834 | 85 |

| 350B | 355,6 | 380 | 655 | 145 | 1475 | 480 | 14 | 13 | 244 | 25 | 216 | 22 | 491 | 50 |

| 400A | 406,4 | 430 | 705 | 160 | 1630 | 550 | 28 | 26 | 594 | 61 | 521 | 53 | 1 040 | 106 |

| 400B | 406,4 | 430 | 705 | 160 | 1630 | 550 | 15 | 13,5 | 326 | 33 | 269 | 27 | 657 | 67 |

| 450A | 457,2 | 480 | 745 | 170 | 1810 | 620 | 29 | 26 | 753 | 77 | 612 | 62 | 1 216 | 124 |

| 450B | 457,2 | 480 | 745 | 170 | 1810 | 620 | 14,5 | 13 | 382 | 39 | 292 | 30 | 765 | 78 |

| 500A | 508 | 530 | 790 | 190 | 2040 | 690 | 32 | 29 | 992 | 101 | 757 | 77 | 1 511 | 154 |

| 500B | 508 | 530 | 790 | 190 | 2040 | 690 | 14,5 | 13 | 457 | 47 | 326 | 33 | 912 | 93 |

| 550A | 558,8 | 580 | 840 | 210 | 2240 | 750 | 31 | 28 | 1 131 | 115 | 812 | 83 | 1 619 | 165 |

| 550B | 558,8 | 580 | 840 | 210 | 2240 | 750 | 21 | 19 | 781 | 80 | 541 | 55 | 1 560 | 159 |

| 600 | 609,4 | 630 | 875 | 225 | 2490 | 820 | 33 | 28 | 1 401 | 143 | 948 | 97 | 1 893 | 193 |

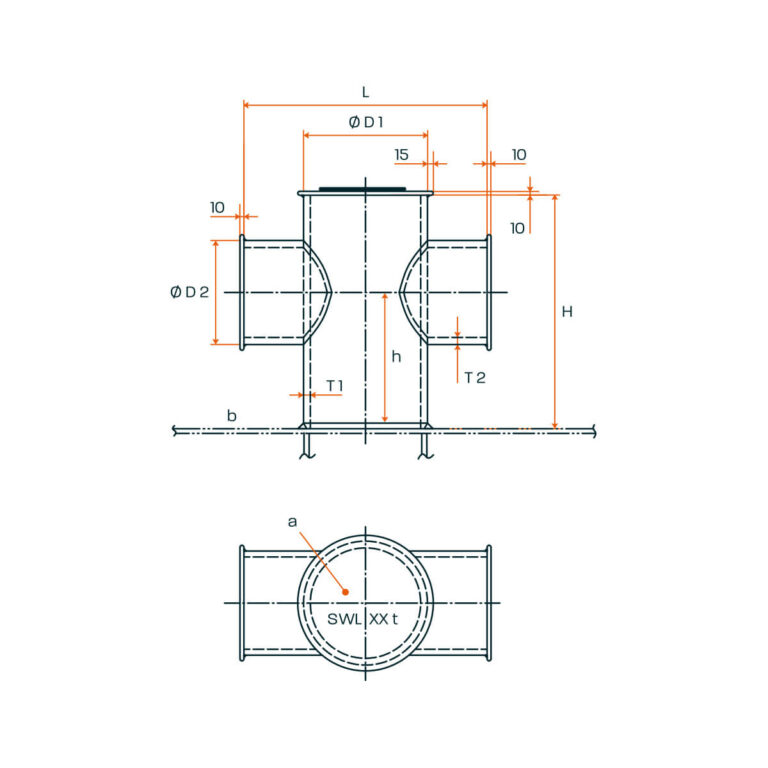

Cruciform bollards are typically used in heavy-duty mooring operations and offshore applications. Their cross-shaped structure provides exceptional strength and stability for high-tension mooring lines.

| Cruciform Bollards – DIMENSIONAL TABLE (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | Dn |

Type | L | D1 | D2 | T1 | T2 | H | h | SWL | C. Weight (kg) | |

| kN | ton | ||||||||||

| 150 | Type A | 350 | 165.2 | 114.3 | 11 | 8.6 | 450 | 225 | 78 | 8 | 37 |

| Type B | 350 | 170 | 120 | 8 | 8 | 450 | 225 | 78 | 8 | 31 | |

| 200 | Type A | 450 | 216.3 | 165.2 | 12.7 | 11 | 500 | 250 | 147 | 15 | 58 |

| Type B | 450 | 220 | 170 | 10 | 8 | 500 | 250 | 147 | 15 | 48 | |

| 250 | Type A | 575 | 267.4 | 216.3 | 15.1 | 12.7 | 600 | 300 | 245 | 25 | 92 |

| Type B | 575 | 270 | 220 | 13 | 10 | 600 | 300 | 245 | 25 | 81 | |

| 300 | Type A | 625 | 318.5 | 267.4 | 17.4 | 15.1 | 600 | 300 | 392 | 40 | 132 |

| Type B | 625 | 320 | 270 | 15 | 12 | 600 | 300 | 392 | 40 | 115 | |

| 350 | Type A | 670 | 355.6 | 267.4 | 19 | 15.1 | 600 | 350 | 491 | 50 | 150 |

| Type B | 670 | 360 | 270 | 16 | 12 | 600 | 350 | 491 | 50 | 130 | |

| 400 | Type A | 720 | 406.4 | 267.4 | 21.4 | 15.1 | 600 | 350 | 736 | 75 | 178 |

| Type B | 720 | 410 | 270 | 19 | 14 | 600 | 350 | 736 | 75 | 165 | |